Water is a vital resource for human life — and for many industrial processes. Water scarcity is a growing global trend, exacerbated by climate change and increasing demand. As major users of water, how can the oil refining and petrochemical sectors improve water management, guarantee supply, and protect the local environment? This Viewpoint explains the current context and outlines strategies to meet the industry’s current and future water challenges.

Due to increasing demand and accelerating climate change, the global availability of fresh water is under unprecedented threat. According to a 2022 assessment of private sector water use by Ceres, a sustainability nonprofit, 42%-79% of watersheds across the globe could reach “ecological tipping points” by 2050. Significant improvements are critical to current water management practices; without them, multiple areas will experience water scarcity.

Like many environmental problems, water scarcity is not a new issue, as highlighted by the Arthur D. Little (ADL) Viewpoint “The Water Margin” back in the early 2000s. However, its impact on both residential and industrial sectors is growing. According to the European Commission, 38% of the EU population and 29% of EU territory are currently affected by water demand exceeding supply.

UNDERSTANDING GLOBAL REGULATORY CONTEXT

Regulatory agencies across multiple countries and regions face the impact of water scarcity and pollution:

-

EU. Member countries of the EU adopted the Water Framework Directive (WFD) in 2000, which stipulated objectives for chemical water quality and ecological targets. The issue of water scarcity and drought was reiterated as a priority in the European Green Deal of 2020. Moreover, water is one of the three main pillars of the EU’s Zero Pollution Action Plan, which aims to achieve a toxin-free society by 2050, with pollution reduced to either zero or levels no longer harmful to nature and humans. This implies action not only downstream, at the level of wastewater treatment plants, but also upstream, where substances are produced and used.

-

US. The Clean Water Act regulates water resource restoration and maintenance activities. Additionally, multiple states have implemented their own regulations around water usage, such as the Texas Water Code and Colorado’s Prior Appropriation System.

-

Asia and Africa. Developing regions often have less strict regulations on water quality and usage, leading to the discharge of untreated chemicals, heavy metals, and microplastics into rivers, streams, and estuaries located along their coasts. However, the United Nations (UN) Food and Agriculture Organization’s (FAO’s) Regional Office for Asia and the Pacific published its Water Scarcity Program (WSP) for Asia–Pacific in 2021. This document aims to support countries facing water scarcity in agriculture to collaborate with external partners to review water scarcity policies, implement tools like consumption-based water management, and realize activities such as the Australian Water Partnership’s Next Generation Irrigation and water tenure.

-

Kingdom of Saudi Arabia (KSA). KSA’s National Water Strategy 2030 set a vision to establish a sustainable water sector that safeguards natural resources and the environment while providing cost-effective supply and high-quality services, contributing to socio-economic development. It consists of 10 key programs spanning from legal and regulatory frameworks to infrastructure restructuring and capacity building, representing a holistic approach to water management and resilience. In this context, in 2020 the new Water Law was issued covering resource management, investment, licensing, and tariff.

THE IMPACTS OF OIL REFINING

Industry is a major user of water resources, with the energy sector consuming 56 billion cubic meters of fresh water every year, according to the International Energy Agency (IEA). Oil refineries and petrochemical facilities are a crucial part of the energy industry, playing a significant role in meeting the world’s energy demands. They are also heavily dependent on water for their ongoing operations.

Mapping link between water scarcity & oil refining

Oil refineries require vast amounts of water for processes and equipment cooling. However, as water availability continues to worsen in many regions around the globe, the availability of water for the oil refining sector becomes increasingly uncertain. It is therefore crucial to examine the impact of water scarcity on the oil refining sector at both a global level and country level to identify potential risks and opportunities for sustainable production.

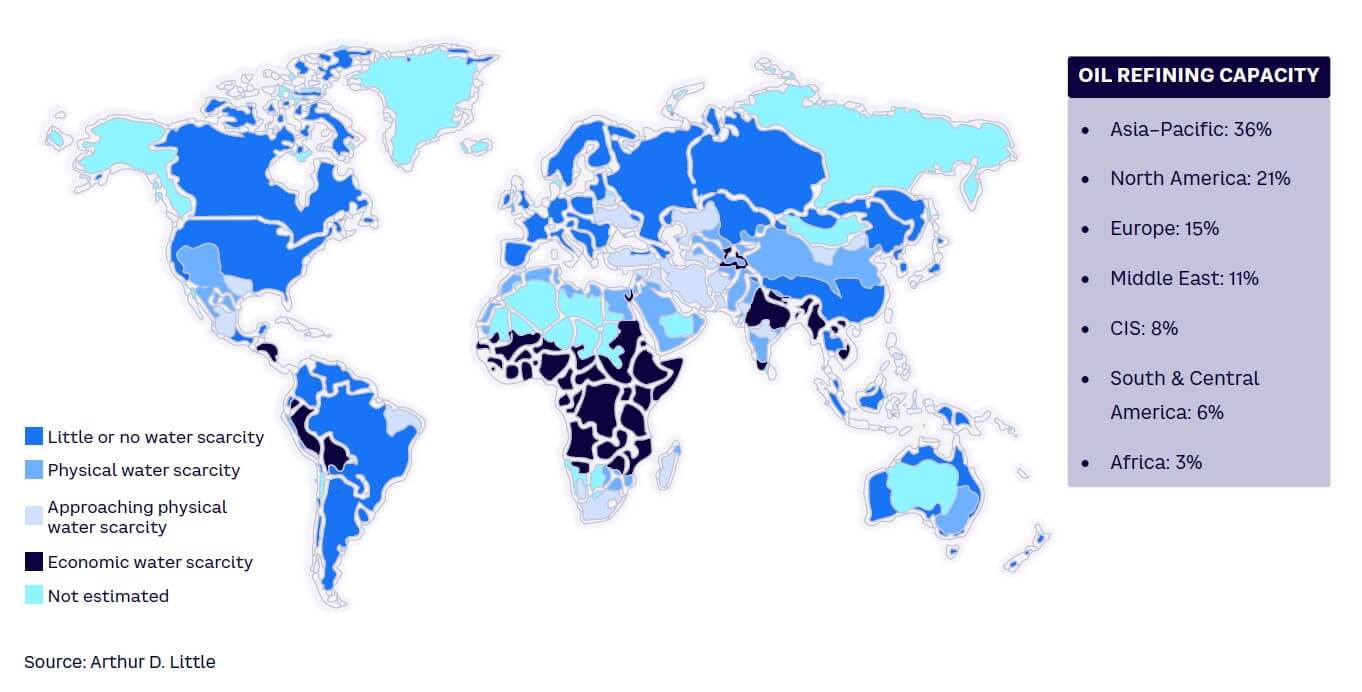

Overlaying the UN water scarcity map with oil refining activities reveals that regions such as Africa, the Middle East, Asia–Pacific, and parts of South and Central America may face significant challenges in sustaining their oil refining capacity due to water scarcity (see Figure 1). Addressing this challenge is critical.

Water is used in multiple areas of refineries (e.g., for cooling towers) to feed boilers for steam generation, as process water, potable water, and sanitary water, and for fire suppression. Cooling water is the largest use.

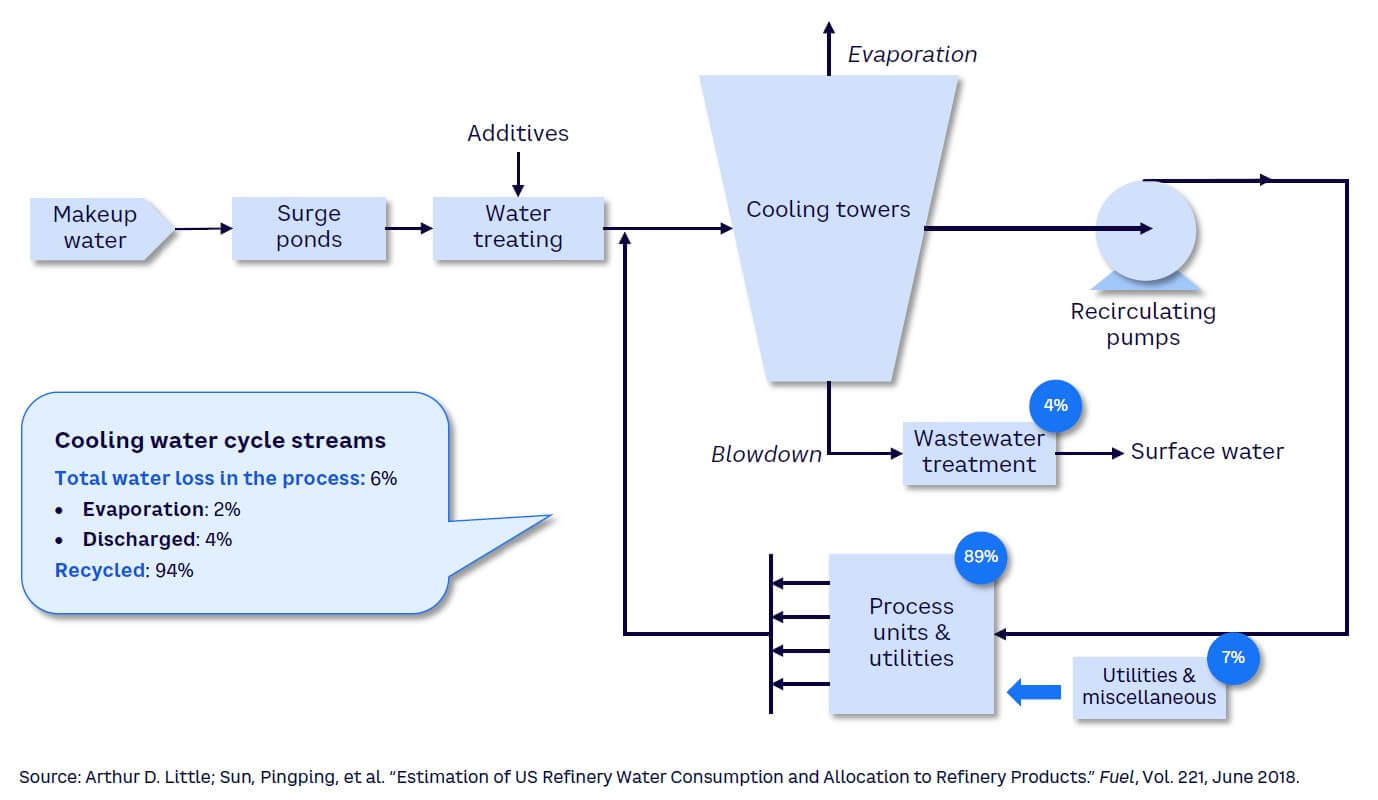

Figure 2 shows the typical flow of cooling water within a high-level representation of a oil refining plant, showing water streams and flow rates. On average, between 0.34-0.47 barrels of water are consumed to process one barrel of crude oil. Six percent of water is lost during the process, 4% is discharged, and 2% evaporates.

Figure 2 also depicts the main water flow in a oil refining plant:

-

The process begins with makeup sources (e.g., freshwater or groundwater wells).

-

This water is then treated to remove impurities and to ensure it meets the plant’s specific water-quality requirements.

-

Treated water is typically sent to the facility’s cooling semi-closed loop, which contains cooling towers and process units:

-

Water is first sent to the cooling towers and then redirected through dedicated pumps to the process units, where it is used to cool equipment and processes.

-

Some of the water used in cooling towers evaporates. Oil refining plants address this by collecting the water used in the process and the makeup stream, then returning it to the cooling towers and process units for reuse.

-

-

This recycling process significantly reduces the plant’s overall water usage and helps minimize the amount of water discharged from the plant. However, even with recycling in place, some water is still lost due to cooling tower evaporation (around 2% of the total), with further volumes (around 4%) discharged from the plant after undergoing wastewater treatment.

-

Wastewater treatment typically involves the removal of any remaining impurities or contaminants before the water is discharged to surface water bodies like rivers or lakes. Treated water must meet strict quality standards to ensure it does not harm the environment or human health.

All of this means that refineries need to reintegrate 6% of the water they use, which runs into thousands of gallons at larger plants. Facilities use water from multiple intake sources. For example, in the US, 72% is from rivers or lakes, 10% is groundwater, and 18% is city or municipal water. Larger refineries tend to use water directly from a lake or river, while smaller ones utilize at least some city or municipal water sources.

ENVIRONMENTAL IMPACTS OF OIL REFINING

Oil refinery operations produce a large number of pollutants and are regulated by environmental laws related to air, land, and water impacts. In terms of water pollution, refineries are potential major contributors to groundwater and surface water contamination. Process wastewater may be highly contaminated by the oil refining process (e.g., equipment leaks and spills, the desalting of crude oil) and contain oil residuals and other hazardous compounds. It is recycled through many stages and undergoes multiple treatment processes before being released into surface waters, with regulations governing the levels of hazardous compounds allowed.

Some refineries use deep-injection wells to dispose of wastewater, with portions ending up in aquifers and groundwater. Sources of wastewater contamination include:

-

Process wastewater from desalting

-

Water from cooling towers

-

Stormwater

-

Distillation/cracking processes

STRATEGIES & APPROACHES TO IMPROVE WATER MANAGEMENT

To meet water scarcity challenges, refineries and petrochemical players need to build proactive, strategic, and effective strategies to minimize water consumption, utilize alternative water sources, and achieve zero process wastewater discharge.

Addressing the challenge requires a five-step approach:

-

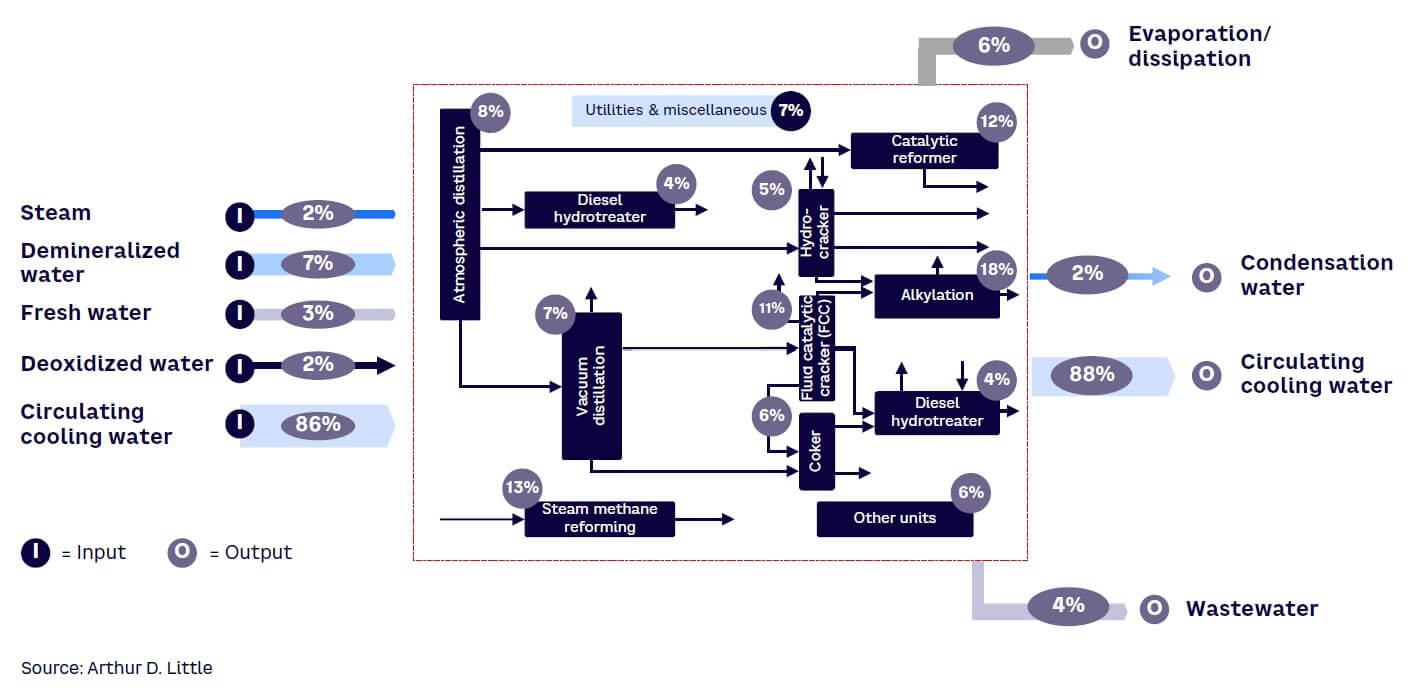

Fully assess water balance. Closely examine water usage across all processes, identifying opportunities for efficiency improvements and areas where water quality changes occur. Figure 3 shows an excerpt from an assessment of a typical refinery, including usual water consumption ratios of main processes. Similar figures can be developed for petrochemical sites.

-

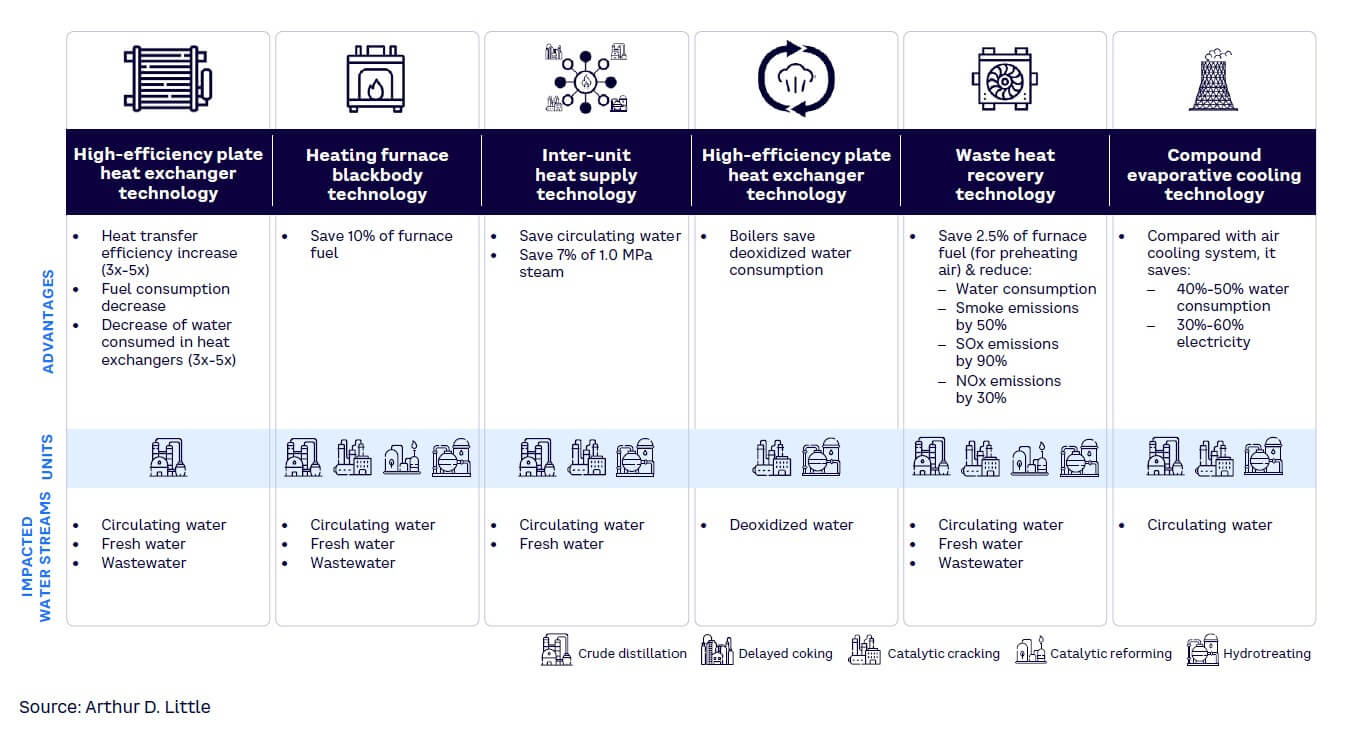

Map water initiatives and prioritize based on cost-benefit analysis. Involve all relevant departments, such as process engineering, R&D, health and safety, and operations, and conduct thorough assessments to identify potential areas for savings in water supply, usage, and treatment, ensuring that cost-effective measures can be implemented. Figure 4 shows a selection of water-saving initiatives, with recommended prioritization based on the impacts on water flows.

-

Set and promote targets for water saving. Establish clear targets for water use, including abstraction, reuse, and wastewater treatment. Focus on workforce engagement to motivate employees to achieve the desired goals.

-

Prioritize processes needing enhancement. Scrutinize each process to determine how water consumption could be reduced, reused, or substituted with lower-quality alternatives (e.g., recycled/discharged water). Example measures could include the substitution of lower-quality groundwater for potable water in process water makeup, the reuse of process water within quality limits, and the recovery of condensate from boilers and steam generators for reuse.

-

Map and select funding opportunities. Explore potential funding sources, particularly from public bodies, to support improved water management. For example, within the EU Taxonomy and EU Green Deal Framework, EU countries have developed national and regional funding schemes for projects that positively contribute to specified environmental goals, including:

-

Climate change mitigation — such as the implementation of a reverse osmosis plant, which creates a more circular semi-closed cooling loop, boosting water recycling and significantly reducing overall consumption.

-

Climate change adaptation — such as enhancing the efficiency of wastewater treatment plants, reducing water blowdown, and therefore minimizing the adverse impacts of both current and anticipated future climate conditions.

-

Circular economy/pollution prevention — such as improving energy consumption metering systems, for example, to identify areas for optimizing and reducing energy usage.

-

Protection of biodiversity — such as implementing a biodiversity offsetting strategy to compensate for any unavoidable negative biodiversity impacts caused by development activities. When a development project (e.g., the expansion of a facility) results in the loss or degradation of natural habitats and biodiversity, offsetting provides a mechanism to restore or enhance biodiversity elsewhere to offset those losses.

Conclusion

RESPONSIBLE WATER MANAGEMENT PRACTICES IS PARAMOUNT

To achieve long-term viability, refineries must address water scarcity challenges by embracing responsible water management practices. Financially, the economics of investing in such initiatives is increasingly favorable due to greater opportunities to access funds from sources focused on the green transition and shareholder willingness to future-proof businesses.

Addressing water scarcity can positively impact key performance dimensions:

-

Competitiveness. Improved processes reduce operating costs, enhance efficiency, and protect operations from potentially higher future water costs, improving margins in a lower-demand environment.

-

Environmental impact. Socially responsible practices directly impact the environment by reducing pollutants and preserving a vital resource for communities and development.

-

Regulatory compliance. Responsible practices position refineries to meet current and future regulatory requirements, anticipating investments and potential penalties.