At the same time, national and international sustainability laws and initiatives require a fundamental shift within global supply chains. It is clear that organizations require a strategic framework that supports decision makers in creating supply chain value by synchronizing supply chain layers beyond short-term and reactive crisis management.

Traditional management fails to address today’s challenges

The game-changing challenges global supply chains face today are symptomatic of a central challenge of today’s supply chain management: (often extreme) fluctuations in demand and supply are a primary driver for supply chain imbalances, especially in fragmented supply chains.

The reasons current supply chain management organizations are unable to cope with these fluctuations are multifaceted. On the organizational supply side, fragmented planning, characterized by functional silos and asynchronous planning horizons, compromises the overall supply chain in numerous ways, such as by nondisclosure of fluctuating production demands between the production and procurement function. Organizations must overcome low levels of cross-functionality and/or cross-site information transparency to find the best possible supply plan and to allow for fast adaption in extreme situations (e.g., pandemics or natural disasters).

On the demand side, various types of demand have emerged and intensified over the last couple of years. Diverse, overarching super trends, such as increasing environmental and social sustainability awareness, have created major pull factors toward sustainable and green products and their components. Moreover, enhanced regulation and consumer awareness have forced supply chains to consider sustainability and environmental aspects in sourcing, transportation, and production.

While planning cycles have traditionally relied on robust demand forecasting, increasingly volatile and unpredictable consumer behavior has forced supply chains to create inherent responsiveness. From the strategic design onward, supply chains must consider the demand boost a simple social media post can create in a totally unforeseen manner. Thus, supply chain synchronization requires a holistic approach incorporating planning for marketing, demand, network, production, and procurement. Moreover, extreme supply chain imbalances are often exacerbated by traditional supply chain management’s inability and inflexibility to act and react to short-term events.

In recent months, the COVID-19 pandemic showed that the existing supply chain infrastructure is vulnerable to sudden disruptions. At the same time, organizations have learned that wildfires, floods, and storms can cripple road, water, power, and telecommunications infrastructure, causing severe short-term supply bottlenecks as well. These challenges have led to a rethinking in supply chain planning toward more resilience and combining supply chain synchronization and lean thinking. Various options exist to mitigate and overcome these risks, such as moving operations closer to the consumers, diversifying the supplier base, introducing dynamic inventory management, or building augmented and data-driven forecasting capabilities to increase supply chain agility. Nowadays, with the support of digital solutions and technologies in the supply chain, these options do not necessarily come with a decrease in cost-efficiency or productivity.

All in all, supply chain leaders must seek out a concept that can create a sustainable and highly productive supply chain with high levels of efficiency. In consideration of this radical transformation pressure, supply chain management must evolve into a truly strategic business function.

Beyond demand-and-supply balancing

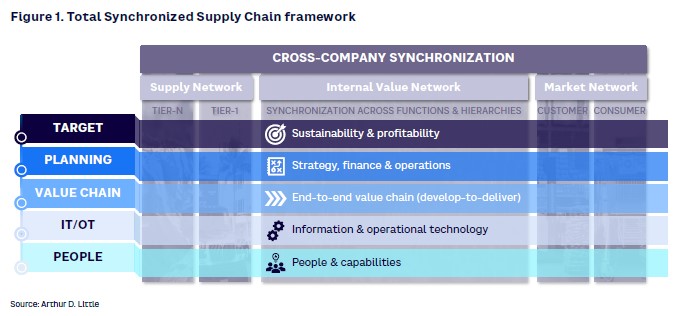

As shown in Figure 1, the Arthur D. Little Total Synchronized Supply Chain framework stands for a strategic, holistic, and integrated end-to-end coordination of the supply chain starting from the supply network across the internal value network to the market network.

The approach integrates supply chain management along five layers: target, planning, value chain, information technology/operational technology (IT/OT), and people:

- Target layer. The classic supply chain management approach focuses first (and sometimes only) on economic-driven targets and KPIs, such as direct sourcing costs or order fulfillment rates. As social, economic, and political awareness toward ecological and social purpose rises, supply chain leaders are becoming increasingly alerted to integrating sustainable and lifecycle-oriented profitability objectives.

An area of growing importance in sustainable supply chain management is human rights, which recently has shifted from being a factor (like fair trade or the UN Sustainable Development Goals) to a tool enabling national security policy.A recent example is the US ban on imports from China of a key material used in manufacturing solar panels due to human rights abuse allegations in Xinjiang.

Sustainable supply chain strategies incorporate ambitious but realistic economic and ecological targets. These may include, for example, a reduction in the environmental footprint of manufacturing sites and logistic services or a strict prohibition of child labor beyond organizational borders. Supply chain targets serve as fundamental and guiding principles for all supply chain–related activities and decisions throughout the supply, value, and market network beyond the organizational border. The aim is to create an organizational push that aims for both sustainable and highly productive targets at the same intensity and effort, addressing every aspect of a supply chain network. - Planning layer. Supply chains may become confusingly complex, requiring supply chain managers to collaborate and interact with a multitude of players in the supply and market network. This often leaves managers struggling to gather the correct information in time to make augmented and data-driven decisions that also consider defined sustainable and highly productive targets. While integration between strategic and operational planning has grown over the past years, a clear connection to companies’ financial planning is often lacking.

Forward-looking supply chain planning must evolve into value-oriented planning rather than pure volume-oriented forecasting. Value-oriented planning enables decision makers to take actions based on the overall impact of the short- and long-term financial impact for the larger business. Real-time scenario planning that considers costs of additional services, complexity of operations along the supply chain, and impact on the environmental footprint must be the basis for educated decision making in planning. A supply chain control tower is one enabler for real-time augmented decision making, integrating internal and external data along the value and information chain, from supplier to consumer. - Value chain layer. Whereas the planning layer addresses strategy, financial, and operations planning, the value chain layer applies to the implementation and realization of plans within the value chain. Traditional value chain management is characterized by silo thinking within organizational and functional borders. An end-to-end approach aims to develop a fully integrated and synchronized value chain from product and service development to the delivery of a product or service to customers and consumers (“develop-to-deliver”).

This approach is based not only on an integrated process and activity flow, but also on a harmonized operating model and system landscape without unnecessary system and operating frictions. As a result of modern value chain synchronization, enterprise-wide decisions are shared cross-functionally, leading to improved operations as well as more visibility and higher resilience. - IT/OT layer. The complexity and volatility of today’s supply chains requires that organizations be able to sense upcoming disruptions as early as possible and respond in real time. This can only be accomplished by applying digital technologies (e.g., Internet of Things (IoT) and machine learning) to capture and analyze the enormous amount of data across the supply chain. Ensuring real-time access to data, such as production plans and production capacity information, are the foundation for integrating a supply chain control tower into the typical system landscape.

The control tower provides real-time information to the responsible supply and production planners, enabling them to identify potential disruptions (e.g., supply and production capacity issues), locate potential alternative production capacities, and evaluate the financial impact of these scenarios. This is just one example of how a synchronized IT/OT layer can drive end-to-end visibility and improve value chain performance. Through targeted digitalization and a data-driven approach, the synchronization of supply chains is amplified across all layers. - People layer. A transformation of the supply chain is not about automating old processes but about imagining new ways of working and finding innovative process-data-system combinations to deliver the transformation. The success of this approach requires people with a blend of new, different, and traditional skills and capabilities.

New technologies and market requirements are forcing supply chain organizations to develop new capabilities, such as automated and synchronized supply chain planning, multi-sourcing decision making, and utilizing end-to-end supply chain transparency in support of digital supply chain control towers. Organizations can close the current skills gap by acquiring external knowledge or by developing skills internally. Bridging the skills gap requires assessment of the complexity of future tasks/skills as well as an evaluation of current organizational competencies.

How to start the synchronization journey

Whereas demand and supply cut through all layers of the Total Synchronized Supply Chain framework, the synchronization of economic and ecological targets also influences strategic, financial, and operational steering decisions (e.g., whether to invest solely in efficient supply chains or in sustainably effective ones as well). Digitalization at all layers is key to provide the fundamental IT architecture and data flow for planning and operations. Recent case examples reveal that a strategic approach brings significant and tangible value (see “Case 1” and “Case 2”). These examples provide insight into how this approach can transform the supply chain to increase productivity, flexibility, and sustainability.

Productivity, flexibility & sustainability are key benefits

To begin to drive ambitions regarding sustainability, an organization must find a balance and synchronization of economic and ecological targets at both the corporate and cross-functional planning levels.

At the corporate level, synchronization might range from planning and developing a circular economy approach toward the overall attestation and certification process of linear supply chains. In circular economy approaches, organizations must consider multiple planning elements, including the 4Rs (reduction, reusability, refurbishment, and recyclability) in product design and quantitative planning that considers replenishment, sourcing, production, distribution, and reverse logistics. Despite its costs in transition and maintenance, sustainability can be a driver of multiple mutual benefits, such as revenue growth based on fulfillment of customers’ demands, cost reduction in terms of energy and material savings, and risk reduction associated with supplier quality.

At the cross-functional level, existing linear supply chains might involve ecological and economic product design as well as sustainable and environmentally friendly packaging. They might also have to source sustainable products and effective production by eliminating harmful byproducts or waste. Finally, organizations might aim to reach sustainable distribution targets that involve environmentally friendly logistics and preferred regional destinations.

Conclusion

Insight for the executive

When synchronizing supply chains, one must go beyond demand-and-supply balancing. A supply chain’s vulnerability to disruptions can be reduced by addressing and linking multiple synchronization layers. To drive exhaustive synchronization, each layer must be assessed and synchronized beyond organizational borders. Since all layers are interconnected, all layers must be addressed in sync.

Overall, organizations should assess the following three areas to initiate and support the journey toward a total synchronized supply chain:

- Synchronization benefit assessment. Assessing the current synchronization, integration, and effectiveness levels of the supply chain, identifying synchronization measures and their potential benefits and impact.

- Future-proof solution design. Developing a future-ready synchronized supply chain target picture (including to-be process, IT architecture, and operating model) to enable better, data-driven decision making; a gap analysis will highlight key synchronization actions to tackle.

- Pilot and roll-out support. Ensuring proper support of the new target concept, including creating a true supply network, living the new operating model, piloting innovative digital technologies like the supply chain control tower, and so on.